September 12, 2019

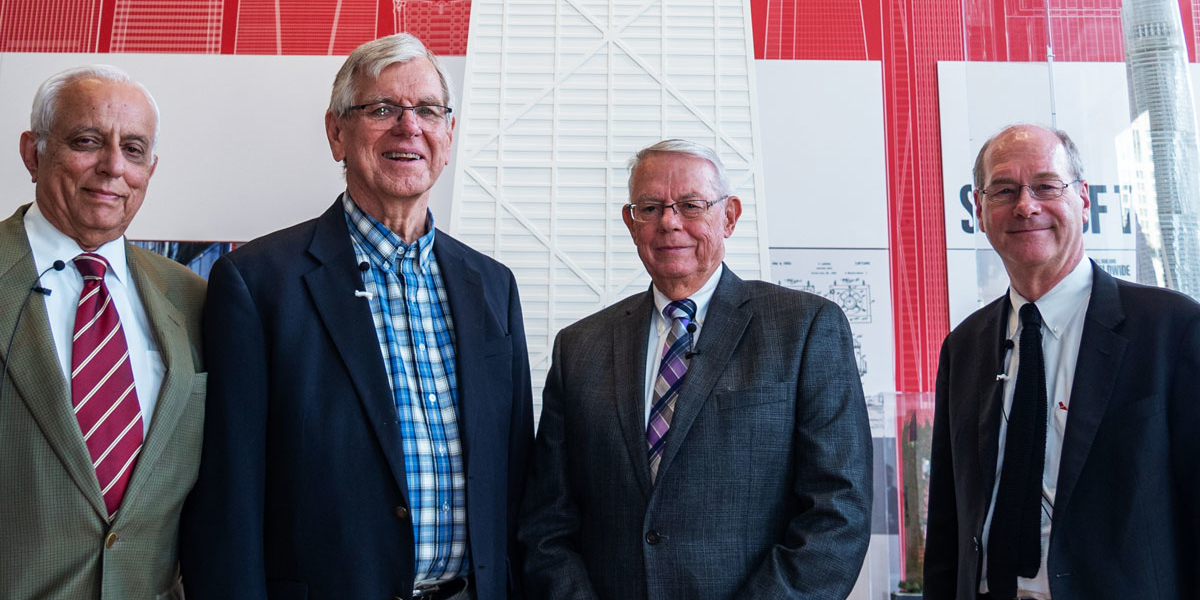

CHICAGO – In the last of the lead-up events to the CTBUH 2019 World Congress / Building Tall lecture series, three members of the original architecture and engineering team behind Chicago’s

John Hancock Center (now 875 North Michigan) recalled the rollicking story of the creation of one of the city’s best-known landmarks. David Ruby, Chairman and Founding Principal, Ruby+Associates; Joseph Calaco, President, CBM Engineers; and Richard Smits, Associate Partner (retired),

Skidmore, Owings & Merrill (SOM) recounted an intimate history of the legendary skyscraper before a packed event hosted at the Chicago Architecture Center (CAC) and conducted in partnership between CAC, CTBUH and the Chicago Committee on High-Rise Buildings (CCHRB). The Hearn Company, managers of 875 Michigan Avenue and owners of its office and parking garage spaces, was the lead event sponsor. The occasion marked the 50

th anniversary of both the tower and the Council.

With

William Baker, Structural Engineering Partner, SOM, doing the moderating, the three individuals commented on the audacious engineering, trials and tribulations, and relative youth of the practitioners working on the project. Baker first provided the context for the creation of the tower, relating the work of Myron Goldsmith on braced towers in the 1950s and that of his thesis co-advisor at the University of Illinois,

Fazlur Khan. Originally conceived as a pair of towers, one office, and one residential, the project became a single tower when it was discovered the structural solution devised by Khan and SOM, the “trussed tube,” with its signature diagonals neatly carrying loads to the corners, would allow for an especially tall building with flexible, column-free floor plates, Baker said.

Smits said he was a “young kid fresh out of IIT [

Illinois Institute of Technology]” when he joined the Hancock project team as coordinating architect in charge of construction documents and administration. Ruby was the project engineer for the American Bridge Division of US Steel, which was the steel erector for the tower. Although it was his first major project, it was so significant, he would later joke with his boss after it was over, “I might as well retire.” Calaco had just graduated from the University of Illinois when he was referred to Chicago for what he thought was an interview with Khan. Instead, he was given a desk and a set of drawings. He described himself as a “computer nerd,” which in 1969 meant feeding punch cards through a machine with 2 kilobytes of memory – which earned him a job calculating loads for a 100-story building right out of college.

Asked to identify why there was a 6-month gap in the construction timeline of the John Hancock Center, the panelists relayed the harrowing tale of one of the columns that started sinking, as it had been placed over a muddy void in the otherwise hard-packed soil. Breaking the news to a site foreman named “Tex” who “thought that ‘mother’ was half a word” was an unpleasant experience, Ruby said.

It did not help matters that an astrology columnist for the Chicago Tribune had already predicted the tower would collapse, Calaco said. Within days, the sinking-column news had made its way to Chicago Mayor Richard J. Daley, who wanted assurances. After a trip to see Paul Weidlinger, a leading structural engineer in New York, Calaco was able to convince everyone that collapse was not imminent. Then “the real fun began,” he said, describing how two teams were dispatched to deal with the issue – one the project engineers, led by Khan, and the other “a team of lawyers and insurance companies.” Calaco Khan had each of 14,000 caissons on the site – some 10 feet (3 meters) in diameter and 100 feet (30 meters) deep – core-sampled with a diamond-tipped drill bit from an oilfield in Oklahoma. Fortunately, only the single problematic column needed to be re-piled. This added considerable time to the schedule, and it was openly questioned whether the project would continue. As “luck” would have it, a few weeks into the column forensics operation, the lead developer went bankrupt, and the John Hancock Insurance Company, one of the underwriters, assumed responsibility for the project.

The mayor later made a reappearance for the setting ceremony for the first angled column. In anticipation of this auspicious moment, Ruby recounted how he had helped design a hinge system so that the massive corner piece could be lifted directly with two cranes from a truck into position – there was no lay-down area on the site, and no way to test the operation. As it turned out, a city prohibition on heavy trucks outside the hours of 9:00 a.m. to 3:00 p.m. didn’t stop the erection crew, led by “Tex,” from practicing the lift the night before at 4:30 a.m.

At one point, Baker showed a slide of the project team taken on the site, asking, “How old are these people?” Graham was 40; Khan, 35; the three men on the stage were in their mid-20s. “They often said the Hancock was built by kids,” Smits quipped. “That’s not far from the truth.”